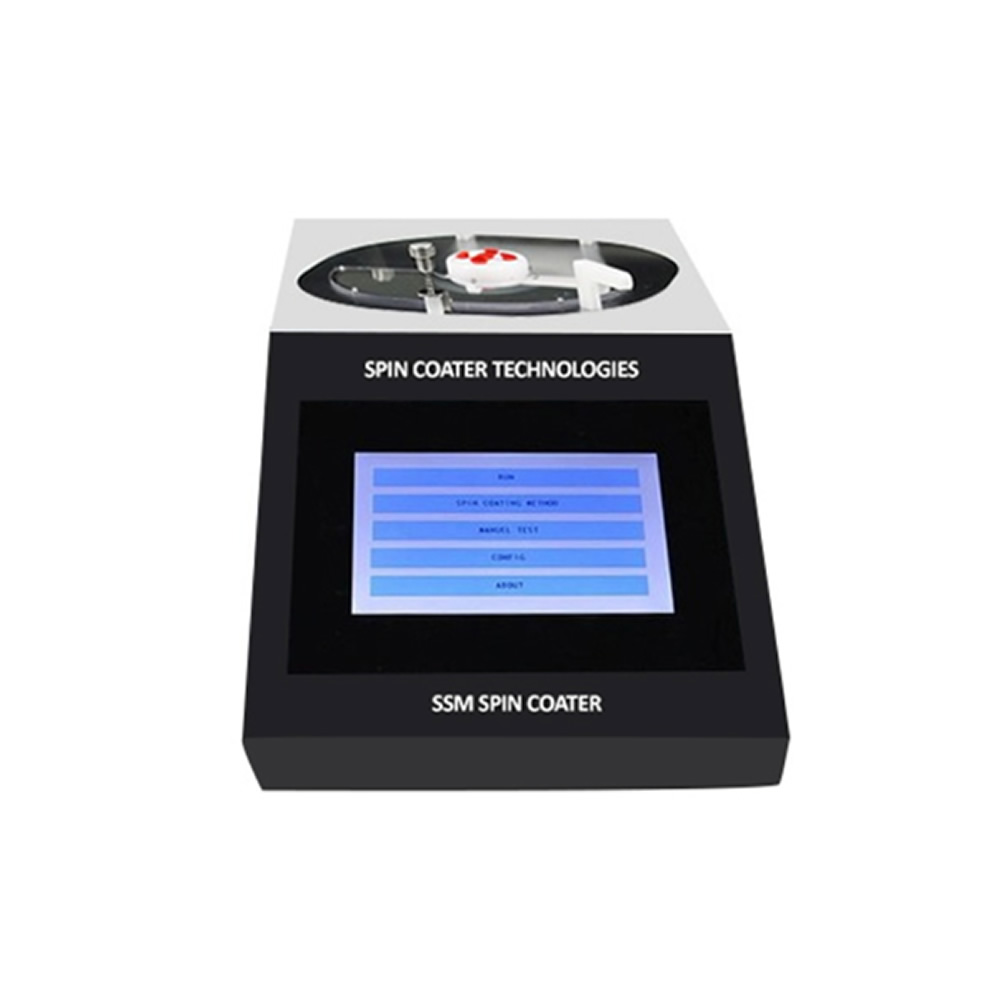

SC X3

Models SPIN COATERS

SPIN COATER SC-PHYS5

TECHNICAL DATA

Spin coater X5

Static Spin coating method

Spin rate: 100-8000 RPM

Speed resolution 1 RPM

Film thickness 10mm to 10 m

Easy to use and maintenance free design •Rotational

LCD touch screen

Vacuum pump

Vacuum chuck

Accelerations minimum 5000 rpm/s

Vacuum Pump

3 Years Warranty

Spin Coater Theory

Spin coating has been used to prepare thin films for various applications. A small puddle of a fluid material onto the center of a substrate is spin coated the on substrate at high speed. Centripetal acceleration causes the formation of a thin film of material on the substrate. The film thickness depends on the solution properties such as viscosity, drying rate, percent solids, surface tension, etc. and RPM and coating time. One of the most important factors in spin coating is repeatability, as subtle variations in the parameters that define a spin-coating process can result in drastic variations in the coated film. A typical spin process consists of a dispense step in which the resin fluid is deposited onto the substrate surface, a high speed spin step to thin the fluid, and a drying step to eliminate excess solvents from the resulting film.

The spin coating methods are static spin coating, dynamic spin coating and multi rpm coating methods.

Static spin coating method is simply depositing a small puddle of solution on or near the center of the substrate. This can range from 1 to 10 ml depending on the viscosity of the solution and the size of the substrate to be coated. Higher viscosity and or larger substrates typically require a larger puddle to ensure full coverage of the substrate during the high speed spin step.

Spin Speed

Spin speed is one of the most important factors in spin coating. The speed (rpm) affects the degree of centrifugal force applied to the resin and the turbulence of the air immediately above it. Relatively minor speed variations at this stage can result in large thickness changes. Film thickness is largely a balance between the force applied to shear the fluid resin towards the edge of the substrate and the drying rate of the resin. As the resin dries, the viscosity increases until the radial force of the spin process can no longer move the resin over the surface. At this point, the film thickness will not decrease significantly with increased spin time. All Cee® spin coating systems are specified to be repeatable to within ±0.2 rpm at all speeds.

ESSC-X5 spin coater has

- Static spin coating

In this method, speed of spin coater is zero and it send a message to user to drop the solution onto substrate and then, it reaches to constant speed and it starts the coating process for a certain time.

3 years warranty, 10 years spare parts supply, service commitment