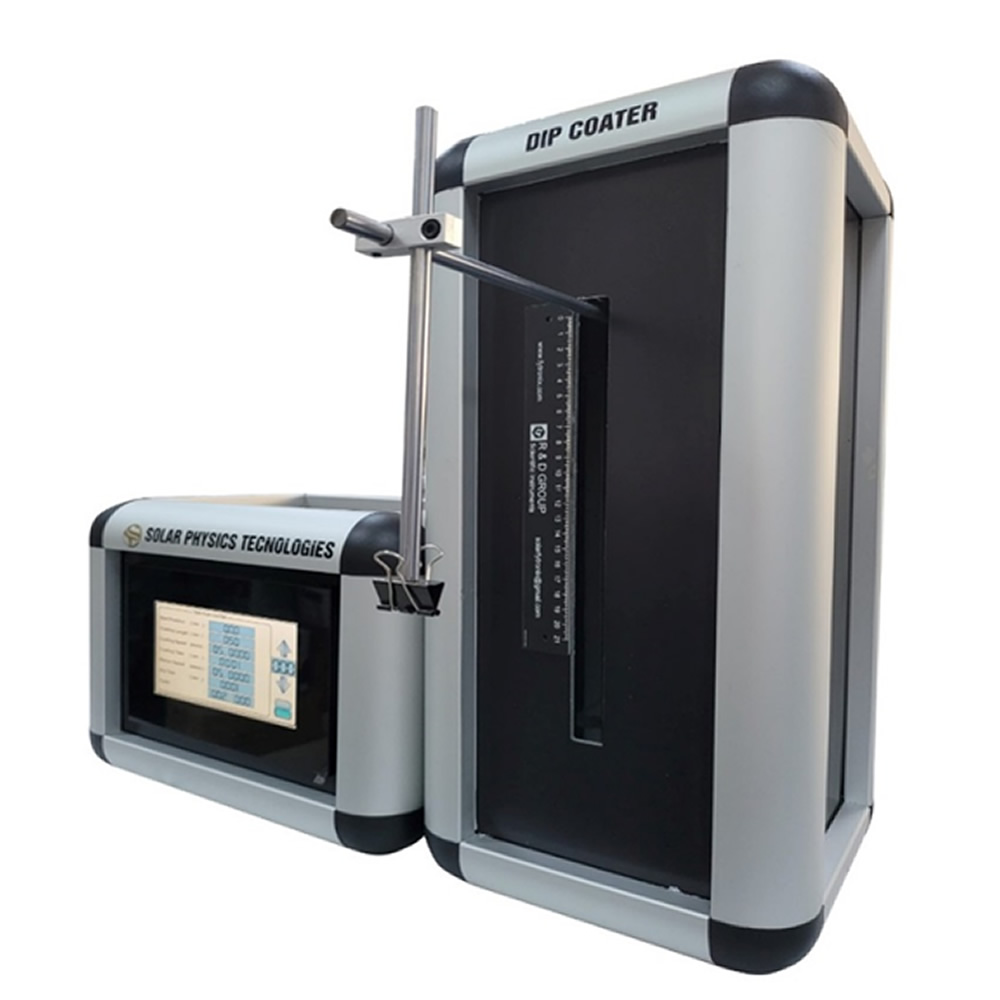

DC X7

Models DIP COATERS

DIP COATER DC-X7

Dip-coating process is one of the commonly used liquid-phase deposition method for the formation of thin films. The technology of this process is based on dipping a substrate into a solution at a controlled rate. After the liquid component of this solution is dried, a solid thin film is remained on the substrate. Thus, the importance of the adhesion and cohesive forces between the dipped substrate and the solution is relevant in the process.

Film thickness can be determined by the following relation

Where V is the linear speed, is viscosity, is the density and g is the acceleration of gravity, 980 cm/s2.

SOLARPHYSTECH DIP COATER

SPECIFICATIONS

7 Inch Touch Screen

Speed: 0-50mm/s, speed be adjusted for dipping or withdrawal

Speed resolution: 0.01 mm/s

Variable dipping speed: 0-40 mm/s

Variable withdrawal speed: 0-40 mm/s

Cycles:1-10000

Duration time for dipping: 1-9999 second

Duration time for withdrawal: 1-9999 second

Travel distance: 0-100 mm or more

Distance between solution: 0-200mm

Programmable dip coater

Power Supply: DC 24V

Power Voltage: 98- 220 V

Dimensions: 200mmx350mmx300 mm or equivalent size or extendable size

2 Years Warranty

DIP COATER

SOLARPHYSTECH DIP COATER is a tool to growth thin film or quantum dots thin films. This DIP coater is widely used in ındustry and academia. The film thickness of the films is controlled by the Ph of solution or dipping cycle of the coater. The rate of withdrawal can be controlled with a high degree of accuracy and reproducibility.